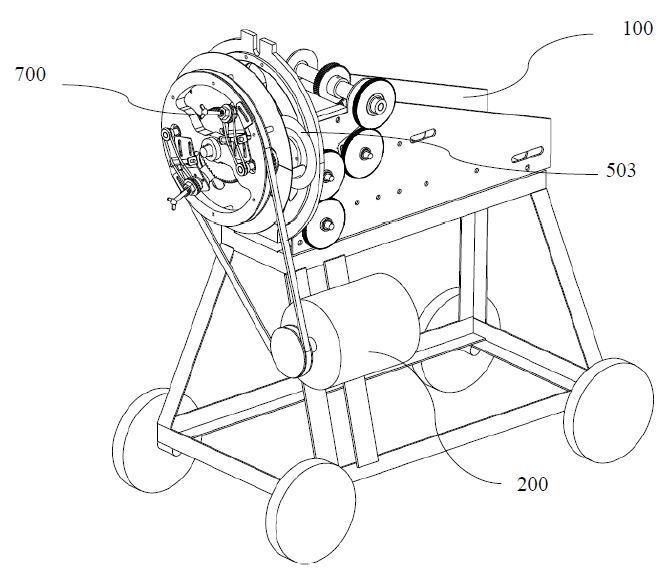

Mesin pemotong tembakau tipe bilah melingkar ganda dengan penajaman bilah otomatis dan mekanisme pengumpanan dari penemuan saat ini yang terdiri atas mekanisme pengumpanan (100) berfungsi untuk mengangkut daun tembakau ke dalam saluran pemotong (101) yang terhubung ke motor AC (200) berfungsi untuk menggerakkan katrol (201) yang terhubung ke rangkaian roda gigi (300), terdiri atas roda gigi cacing (301) dan roda gigi taji (302) dan kemudian terhubung ke rol penggerak konveyor (400) dan mekanisme pemotong (500) berada di sebelah saluran pemotong (101) dan terhubung ke mekanisme penyapu (600) dan mekanisme penajam (700) yang dicirikan dengan rasio rangkaian roda gigi (300) yang disesuaikan untuk mengendalikan ukuran strip tembakau parut yang memiliki rasio rangkaian roda gigi dalam kisaran 1:50 hingga 1:150 dan ukuran strip parut dalam kisaran 0,3-1,5 mm.

Twin circular blades type tobacco cutting machine with automatic blade sharpening and feeding mechanisms of the present invention comprising the feeding (100) mechanism performs to covey tobacco leaves into the cutting channel (101) which is connected to the AC motor (200) performs to drive the pulley (201) which is connected to gear set (300), consists of worm gear (301) and spur gears (302) and is then connected to the conveyor drive rollers (400) and the cutting mechanisms (500) is next to cutting channel (101) and connect to the sweeping mechanism (600) and the sharpening mechanisms (700) characterized in that gear set (300) ratio is adjusted to control the size of shredded tobacco stripes which have the gear set ratio in the range of 1:50 to 1:150 and shredded stripe size is in the range of 0.3-1.5 mm.

| Year | Validity Start | Validity End | Payment |

|---|